Alessandro Rush

Product Design

Aluminium Project:

Ring Razor

For this project I was tasked with creating a product made of at least 70% aluminium, including physical models and a presentation banner. I chose to design a new wet razor - including both the body and blade sections - making sure to achieve a clear environmental improvement over traditional store-bought products.

Sketches & Development

The sketches represent different form ideas for the main body of the razor, varying from traditionally- shaped products to some more unorthodox designs. I selected my favourites from the different designs and then did some additional form sketches to narrow down the shortlist. At this point I selected four concepts that I felt had the best potential, not only in terms of design and comfort but also of originality.

The four concepts in the images showcase a quick one-part CAD model of my favourite designs. For each of the concepts I also made a foam model and asked different people to try them to see if they were comfortable to use. The stick razor did fairly well since it was a shape that everyone was already used to, whilst the ball handle razor performed the worst due to being slightly too large and chunky. The ring razor comfortably stayed on the hand, but occasionally slid around the finger when pressure was applied to the blade. The pinch razor was slightly too small to be held easily. Combining the ring razor and the pinch razor, on the other hand, enabled me to create a product that is easy to hold while also having a good grip to prevent it from sliding (see last image on the sketches slider).

CAD Design

For the final design I decided to go for an edited version of the ring razor.

Main Body

The main body consists of a main ring where the finger is inserted. The ring has a gap on the back to enable the ring diameter to flex and to allow a more comfortable fit, with the ring needing to be easily removable. A thumb grip is added to the front of this, a feature that gives the user a firm hold on the razor and prevents it from sliding backwards when pressure is put on the razor head during shaving. The thumb grip curves outwards toward the top to ensure that the thumb has a comfortable resting position and cannot slip.

Razor Head

The razor head has several features that are already included in current razor blade units, such as a skin guard at the bottom to stretch the skin. This ensures that it is flat for shaving and therefore reduces cuts. There are also indents where lubrication strips can be inserted. These are located above and below the blades themselves. In addition, the razor head has a stopper at the bottom of the component that interacts with the main body to prevent it from over-rotating. Finally, the razor head also has a small back plate which serves as a guide for a metal strip to push the component back to its resting position.

Changeable Blade Part

The Blade

The blade part contains the main support rig and four individual blades. The blades are inserted into the support rig by sliding them into multiple aligned slots, and to keep the blades firmly in place two small components of the rig are then folded down.

How the Blade Part Fits

To fit the blade part to the razor head there are two slots along both sides of the main rig. These slots are perfectly aligned with two pillars fitted on the corresponding sides of the bottom of the razor head. The blade part slides onto the bottom of the razor head, with the back plate acting as a further guide. The razor head top then fits onto the pillars extending from the razor head bottom. Finally, the razor head top slides backwards, locking the top and bottom part of the razor head and firmly securing the blade part in the middle (see storyboard for a visual of how this works on the model).

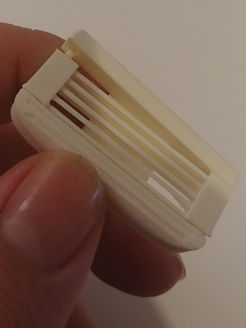

3D Prints

The next step on this project was to make a model of the product. Because of its size the best approach for the model was to 3D-print the different parts as set out in the images below.

3 different kinds of razor head parts were made:

- a single-block version in which the individual blades were represented by in a single filled area and the parts were all in one piece;

- a slightly more detailed head in which the individual blades were visible with the parts again all in one piece;

- and finally a fully working model consisting of 3 parts: the bottom, the top and the blade section.

Storyboard

Push Back

For the razor to function properly it needs to have a force pushing back onto the razor head to ensure that the razor is always in contact with the skin. Some flexibility is always needed, however, since this enables the razor to adjust to the contours of the face. To solve this issue I decided to add a strip at the back of the razor; when pressure is applied to the razor head this leans back and bends the strip, but when the pressure is released the strip pushes back to its original position, moving the razor head forward again.

N.B.: on the model the strip was made out of a thin piece of plastic to achieve the desired resistance.

Changing the Blade

The images below show how the removable blade part can be changed on the model - this process has already been explained in the blade part section above (use the arrows to navigate through the pictures)

For this stage I also created a quick video showing how simple and quick the blade-changing process really is (see video below).

Environmental Study

For this I used CESedupac to determine the difference in carbon footprint between my razor and a product by Xprt Razor.

Razor Body

When looking at the different Co2 Footprints of the Xprt Razor - which is made out of ABS and magnesium alloys - and the Ring Razor - which is entirely made out of aluminium - the two are actually fairly similar. The Xprt has a footprint of 0.129Kg and the Ring Razor one of 0.124 Kg, so the difference between them is 0.005 Kg. It should also be borne in mind that the top and bottom parts of the head on the Ring Razor are actually part of the main body, whilst on the Xprt Razor they are within the disposable blade part.

Razor Blade Part

Unlike in the razor body part (were the difference is only slight) the difference in Co2 Footprint in this case is quite significant. The Co2 Footprint of the Xprt Razor during its lifetime is 0.0143 Kg per changeable part. Whilst in the Ring Razor the equivalent Co2 Footprint is 0.00686 Kg, which gives it a total difference of 0.00744 Kg.

Lifetime difference

Assumptions:

- A person shaves for 62 years, changing razor heads every 10 days (totalling 2,263 different razor heads in a lifetime).

- He changes the razor body in the Xprt Razor every 2 years (against only one lifetime purchase for the more durable, aluminium Ring Razor).

CO2 Footprint for the Xprt Razor:

Firstly the total amount of Co2 Footprint of a head (0.0143) is multiplied by the amount of heads used in a lifetime (2263)

0.0143x2263= 32.3609 (the total Co2 footprint of the heads in a lifetime in Kg)

Then the number of razor bodies bought by the individual needs to be calculated: he shaves for 62 years, which is divided by 2 per year for a total of 31 razor bodies.

To find out the Co2 Footprint, the Co2 footprint in Kg (0.129) is multiplied by 31.

31x0.129= 3.999 kg (the total Co2 footprint of razor bodies used in the lifetime)

Finally, to calculate final figure we just need to add the number for the razor heads used in a lifetime to that of the razor bodies used in a lifetime.

32.3609+3.999= 36.608

36.608 kg of Co2 footprint is released in materials and manufacturing processes for the razor heads and bodies used in a single person's lifespan (excluding transportation).

CO2 Footprint for the Ring Razor:

First of all we need to find out the total Co2 footprint in an individual's life with the Ring Razor.

The total number of razor blade parts bought in a lifetime is 2263. This number needs to be multiplied by 0.00686, which will give the Co2 footprint for all the changeable parts used in a lifetime.

2263x0.00686= 15.52418 (Kg)

Then the Co2 Footprint of buying the razor bodies themselves needs to be calculated (which assumes the same amount as for the Xprt Razor, even though the Ring Razor will probably last longer in reality). 31 will be bought and the Co2 Footprint for a single body is 0.124Kg.

31x0.124= 3.844

Adding the two numbers together gives the total amount of Co2 Footprint produced by using the razors over a person's lifetime.

3.844+15.52418= 19.36818 (Kg)

19.368 kg of Co2 footprint is released in materials and manufacturing processes for the razor heads and bodies used in a single person's lifespan (excluding transportation).

Difference:

Finally, to find out how much less Co2 footprint the Ring Razor produces, 19.368 is subtracted from 36.608 (rounded to the gram).

36.608-19.368= 17.24

The difference between the two razors (in favour of the Ring Razor) is 17.24 Kg of Co2 Footprint over a person's lifetime.